We are always pleased to hear how our collaborative projects have continued to benefit industry long after the initial work has come to an end. In November 2017, we received information from Dr Jano van Hemert, Imaging Research Manager at Optos who stated that a collaborative project we supported in 2014-15 has resulted in a permanent 20% increase in yield in a major component in Optos systems.

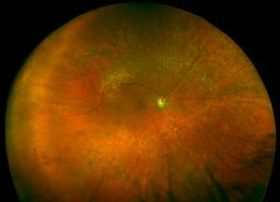

Optos is a leading medical technology company specialising in the design, development, manufacture and marketing of devices to eyecare professionals for improved patient care. Its core devices produce ultra widefield, high-resolution digital images of over 80% of the retina.

Quality Assurance (QA) is carried out manually by highly-specialised staff. For a project on automated artefact detection for scanning laser ophthalmoscopes, Optos worked with CENSIS and the University of Glasgow to develop an automated QA process. Manual QA limits the number of devices processed per day and is subject to conflict in judgement. Optos has adopted the automated QA in the manufacturing process allowing image quality issues to be identified earlier.

This project has led to significant savings for Optos, specifically a permanent 20% increase in yield in a major component in Optos systems.

The generic image-quality algorithm is relevant to a wide range of application areas such as:

- Earth observation (radar-imaging and satellite-imaging)

- Medical imaging (brain, cardiac and full body scans)

- Food and drink (hyperspectral and microscopy)